STANZTECHNIK VOM EXPERTEN

Qualität. Erfahrung. Kompetenz.

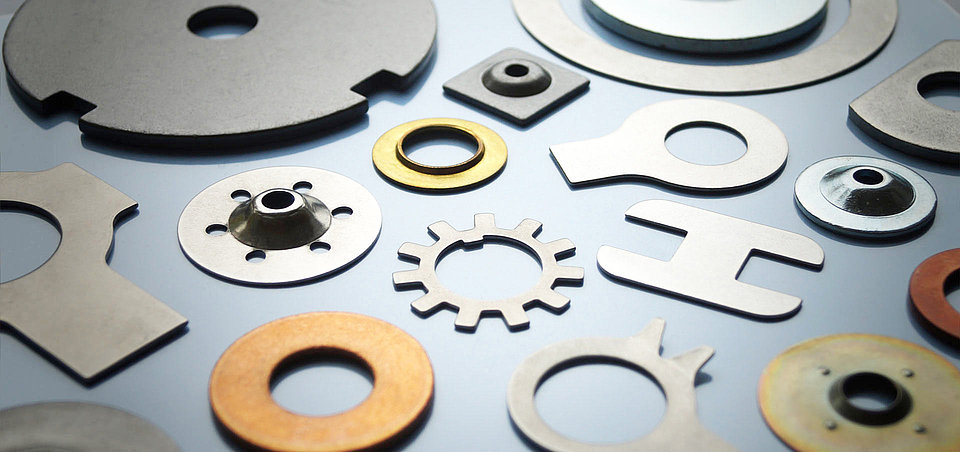

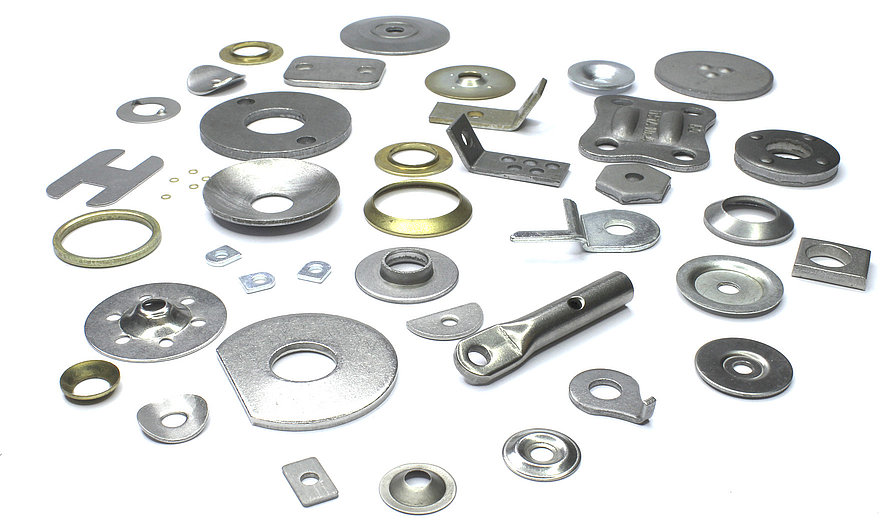

Wir sind Ihr Spezialist für gestanzte Produkte aus Stahl, Edelstahl, NE-Metallen, Sonderwerkstoffen und Sonderlegierungen.

Als passioniertes Traditionsunternehmen bieten wir Ihnen hochwertige Stanzteile nach DIN / ISO Normen und nach Kundenwunsch.

INNOVATIV UND INHABERGEFÜHRT

Leidenschaft und Tradition aus dem Sauerland

Als inhabergeführtes Familienunternehmen aus dem Sauerland, stehen wir seit 1966 für Präzision, Flexibilität und Zuverlässigkeit. Höchste Qualitätsstandards und individuelle Lösungswege machen uns international erfolgreich.

IHR EXPERTE FÜR’S KOMPLEXE

Präzise. Verlässlich. Und spezialisiert.

Wir liefern Stanzteile für zahlreiche Branchen und Kunden auf der ganzen Welt. Durch unsere Spezialisierung auf Sonderlegierungen und Sonderverfahren sind wir Ihr Partner für komplexe Projekte. Verschiedenste Werkstoffe, Durchmesser, Dicken und Veredelungen machen unser umfangreiches Portfolio aus.

Gute Gründe!

KURZE LIEFERZEITEN

Unser großes Vormateriallager ermöglicht schnelle Reaktionszeiten!

SONDERLEGIERUNGEN

Besonderes Know-How besitzen wir in der Verarbeitung von Sonderwerkstoffen.

SORTIERUNG

Wir können Ihre Ware 100% optoelektronisch sortieren.

VERPACKUNG

Wir verpacken Ihre Ware in Standardkartons oder auch in individuelle Behältnisse.

SPEKTRALANALYSE

Durch unser eigenes Spektrometer analysieren wir Materialien präzise und zuverlässig.